he applications of NMR and MR imaging in industry are widespread and involve the analysis of both inorganic and organic compounds. Routine examinations of chemicals are probably the most common applications.

he applications of NMR and MR imaging in industry are widespread and involve the analysis of both inorganic and organic compounds. Routine examinations of chemicals are probably the most common applications.

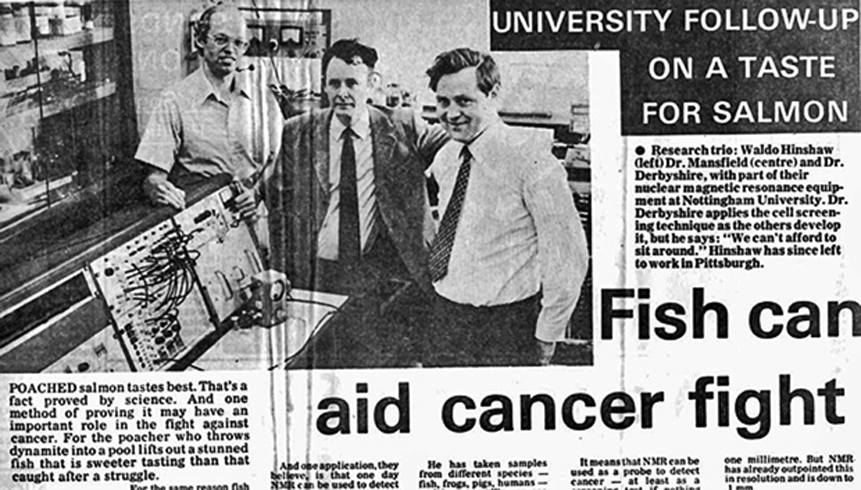

However, the NMR technique is sufficiently flexible to be used, for example, to measure the water-fat ratio in foods (Figure 19-01), monitor the flow of corrosive fluids in pipes, or to study the complex structures of molecules, among them catalysts.

Figure 19-01:

Nottingham Evening Post, 22 October 1974: Waldo Hinshaw, Peter Mansfield, and Bill Derbyshire — and their NMR equipment. Derbyshire worked on relaxation time measurements of fish muscle and the change of taste of salmon after its violent death. More applications in food science followed rapidly.

This chapter wants to give a general idea of possible applications. The overview is not meant to be exhaustive, but it shows some highlights. It also underlines the difficulties, challenges, and possibilities of interdisciplinary research and teaching.

Industrial applications can be divided into chemical, biological, paramedical (protein), data processing, and nondestructive testing.

General Remarks

General Remarks

Hydrogen (¹H) and carbon (¹³C) NMR spectroscopy of solutions of chemicals are indispensable to the organic chemist in identifying the products of the latest reaction. The analysis is quick and simple and does not require an especially pure sample. This type of work is probably the most common type of NMR work done throughout the world and will continue to be so for many years. Yet, it does not begin to hint at the enormous versatility of the NMR technique and the wide range of information which can be obtained from different systems.

Oil and Coal Analysis

Oil and Coal Analysis

Analysis of low molecular weight fractions of oils can be done by NMR, although other techniques do exist. The higher molecular weight fractions which are very viscous or even solid are more difficult to analyze, but solid-state NMR techniques can be very useful.

Solid-state ¹³C NMR has been performed on kerogens (an immature type of coal). The information obtained when applied in conjunction with other types of analysis can be used to predict if the kerogen comes from a site which is gas-forming or oil-forming. Such information is extremely valuable when planning an exploration and drilling program. Among the possible applications in this area is the development of a transportable MRI/MRS system which can be flown into a potential drilling region.

Catalysts called zeolites are used in large quantities by the oil industry to crack the higher molecular weight fractions to produce the smaller carbon molecules used in car and heavy vehicle fuels. The zeolites are a complicated group of molecules composed mostly of silicon and aluminum.

Solid-state silicon-29 (²⁹Si) and aluminium-27 (²⁷Al) NMR have been used extensively to study the structure of these molecules since an understanding of the way they work can lead to the choosing or designing of more efficient types of catalysts.

Flow in Pipelines

Flow in Pipelines

The accurate measurement of flow in pipes is a difficult problem for many industries. For instance, oil in pipes (or even pipelines), fluidized coal, and corrosive fluids have all been measured with NMR, and a commercial NMR flow-meter has been available since 1968. The non-invasive nature of NMR makes it extremely suitable for systems with unpleasant chemicals or extreme pressures, but despite excellent results in a few key examples there is room for much greater use of NMR monitoring of flow, e.g., flow-meters for oil-pipelines with simultaneous qualitative assessment of the transported oil.

Drilling Cores

Drilling Cores

There has been quite a lot of effort put into spectroscopic and imaging studies of drilling cores. The spectroscopic studies have reported correlations between the NMR results and the mineral content, the pore geometry, and the surface chemistry of these rocks. It is hoped that this will either lead to new insights into the geology of the rocks or that NMR will be a quicker, simpler, or cheaper method at obtaining the same information.

MR imaging is being used to get maps of the three-dimensional distribution of oil and water in the cores and eventually will be able to monitor the flow of oil and water through cores. This information is vital to the models used to predict oil extraction from oilfields, where a 1% improvement represents millions of dollars of income gained or lost.

MR imaging can also be used to image ice cores from glaciers and polar permafrost regions.

Plastics and Polymers

Plastics and Polymers

Some samples are mainly of interest as solids. Important examples are found in polymer science where it is the properties of the solid which are important and not the individual subunits which go to make up the solid.

Solid-state NMR is used to study how plastics are put together, to relate their chemistry with their known physical properties. This information can be used to help improve the plastics and develop new ones. There are very few alternatives to NMR for getting this type of information from polymers.

Liquid Crystals

Liquid Crystals

Liquid crystals are used in watches, calculators, and television and computer screens. They are also very difficult to study by other means than NMR. Just like the plastics, information about the packing of the molecules shows how structure relates to functional properties and so can help in creating new products.

Pharmaceuticals

Pharmaceuticals

High resolution NMR is a valuable tool to use when identifying and characterizing new drug molecules and their binding features. It is possible for molecules to exist in two or more different forms or polymorphs in the solid state. Solid-state NMR can be used to detect this. The polymorphs may have different biological activity which may cause a manufacturer to try to isolate one or another form.

Furthermore it might prove possible for a competitor to by-pass patents if the existence of polymorphs has not been accurately documented.

Magnetic resonance is also being applied to observe properties and interactions of pharmaceuticals with proteins, perform toxicology studies, and determining concentrations.

Cement and Concrete

Cement and Concrete

The study of the hydration process in cement is of great interest to the industry. Increasing the speed of hydration and the degree of hydration are both highly desirable since they increase the speed of setting and the strength of the concrete.

Until it was shown that they can clearly be seen in solid-state ²⁹Si spectra of cement, both processes were rather difficult to quantify. Changes in the concrete can be followed over periods of 90 days or more and thereby one can characterize the effect of different additives on the curing process.

Wood Pulp and Paper

Wood Pulp and Paper

The pulp and paper industry uses the complex mixture of high molecular weight compounds from wood pulp as its raw material. Solid-state NMR has been used to characterize the pulp and it can be used to determine the effect of different mechanical or chemical treatments of the type of pulp produced. Possibilities might also exist for the monitoring of pulp production in the factory.

Explosives

Explosives

It is not possible (or at least not safe) to examine explosives directly. However, it is possible to study chemical analogues of explosives like acetyl cellulose to improve understanding of the chemical structure of such materials. By relating chemical structure with functional properties one can help in designing of safer and more efficient explosives.

Leather and Rubber

Leather and Rubber

Attempts are being made to replace chromium salts in leather tanning by environmentally friendlier aluminum salts. It seems possible that solid-state ²⁷Al spectroscopy can be used to help to characterize tanned leather. In a similar way, tire rubber can be analyzed.

Imaging of Solid Materials

Imaging of Solid Materials

Imaging of solids is still not very common. Like medical imaging the nucleus being observed is ¹H, but unlike medical imaging where the signal is relatively sharp and long lived, the signal from the proton in solid materials is generally rather difficult to detect since it is a very broad and only lasts for a relatively short time. The purpose of such experiments is to test non-destructively the various plastics and polymers used increasingly in modern manufacturing.

At present most published images are typically of a block of a solid material with holes of varying size drilled in it to demonstrate the resolution of the technique.

There is one example of the use of MRI to observe solid rocket fuel prior to combustion. The packing of the solid fuel can have a large impact upon the burning properties. Conventional analytical techniques would either disturb the packing or prevent the sample being used in an ignition experiment. By the use of solid-state MRI it was possible to image samples before ignition tests and so directly correlate the effect of packing on burning properties.